Hi

there,

I

would like to ask you with regards to measuring TDS. I have did some reading

and searches but am still confused. Would need your help in checking my

understanding and also some qns.

Im

looking to get HM Digital COM-100 which has 4 modes, µS,

mS, ppm

0.5 (NaCl) Scale & 0.7 (442™) Scale. Actually I am interested in using the 442 mode. Based on the

specification it is calibrated by 1413 microsiemens solution supposedly KCl i

think. Im thinking of getting a Eutech 442 300ppm or 50ppm solution to

recalibrate the meter.

- Which mode do i set to when I'm recalibrating with say 300ppm 442 solution?

- Another solution which is from HM digital is a 342ppm NaCl solution.

The

specification noted that 342ppm NaCl = 478ppm in 442. Does it mean that i can

calibrate at 442 mode with 478ppm or just mean that when reading at NaCl mode

it will be 478?

Regards

Ron

Hi Ron,

You may want to read a previous post:How are total dissolved solids (TDS), electrical conductivity (EC) and salinity different

Incidentally, you did not mention what kind of water sample you are testing as that will affect the testing mode you want to use. But I suppose you have a rationale for choosing the 442 mode.

First and foremost, I am not a fan of using TDS for water water quality testing as it is a calculated value and it's relevance rests on the assumption that you have a certain composition of substances in your water sample. I invariably measure EC for all my water quality tests because it is a measured value (this is technically not correct since voltage is the measured value but the correlation between the 2 is strong enough for my purpose) and I DO NOT know what are the substances in my water samples. To me, it only makes sense to measure TDS when you are only dealing with a rather homogeneous water sample which does not fluctuate much in its composition.

The key lies in what conversion factor (CF) to use. If you are dealing with a sample predominantly made up of sodium chloride (NaCl) e.g. seawater, then the typical CF is ~0.5.

The 442 measurement mode refers to a sample made up of 40% sodium sulfate, 40% sodium bicarbonate and 20% sodium chloride. Some users claim that this composition closely resembles natural waters though I believe natural waters vary too widely to follow a simple ratio of 4:4:2 throughout. Anyway, if you are using the 442 mode, the conversion factor is ~0.7.

(In actual fact, the CF is not constant throughout all concentrations of a substance. in general, as the concentration increases, the CF also increases.)

and 684 uS/cm in EC = 0.7 * 684 = 479ppm in 442

But I guess all of us want to get the most bang out of our buck and go for a more economical calibration solution. The next easiest way is then to get an equivalent calibration standard that has the same EC.

For example, if the TDS needs to be calibrated with 479ppm 442 solution in 442 mode, you can substitute with a 342ppm NaCl solution to used in the same 442 mode.

Again, the way to get around all this hassle of TDS and composition is to use the EC mode (uS or mS depending on your range) and calibrate in the same EC mode using calibration standards certified in uS or mS.

Incidentally, you did not mention what kind of water sample you are testing as that will affect the testing mode you want to use. But I suppose you have a rationale for choosing the 442 mode.

First and foremost, I am not a fan of using TDS for water water quality testing as it is a calculated value and it's relevance rests on the assumption that you have a certain composition of substances in your water sample. I invariably measure EC for all my water quality tests because it is a measured value (this is technically not correct since voltage is the measured value but the correlation between the 2 is strong enough for my purpose) and I DO NOT know what are the substances in my water samples. To me, it only makes sense to measure TDS when you are only dealing with a rather homogeneous water sample which does not fluctuate much in its composition.

Mathematically,

TDS (ppm) = conversion factor * EC (uS/cm)The key lies in what conversion factor (CF) to use. If you are dealing with a sample predominantly made up of sodium chloride (NaCl) e.g. seawater, then the typical CF is ~0.5.

The 442 measurement mode refers to a sample made up of 40% sodium sulfate, 40% sodium bicarbonate and 20% sodium chloride. Some users claim that this composition closely resembles natural waters though I believe natural waters vary too widely to follow a simple ratio of 4:4:2 throughout. Anyway, if you are using the 442 mode, the conversion factor is ~0.7.

(In actual fact, the CF is not constant throughout all concentrations of a substance. in general, as the concentration increases, the CF also increases.)

Example

342ppm of NaCl = 342 / 0.5 = 684 uS/cm in ECand 684 uS/cm in EC = 0.7 * 684 = 479ppm in 442

Calibration

I suppose the easiest way to calibrate is to follow the supplier's instructions as they are. I have no experience with your particular model of TDS tester and do not know what kind of calibration standards are required.But I guess all of us want to get the most bang out of our buck and go for a more economical calibration solution. The next easiest way is then to get an equivalent calibration standard that has the same EC.

For example, if the TDS needs to be calibrated with 479ppm 442 solution in 442 mode, you can substitute with a 342ppm NaCl solution to used in the same 442 mode.

Again, the way to get around all this hassle of TDS and composition is to use the EC mode (uS or mS depending on your range) and calibrate in the same EC mode using calibration standards certified in uS or mS.

|

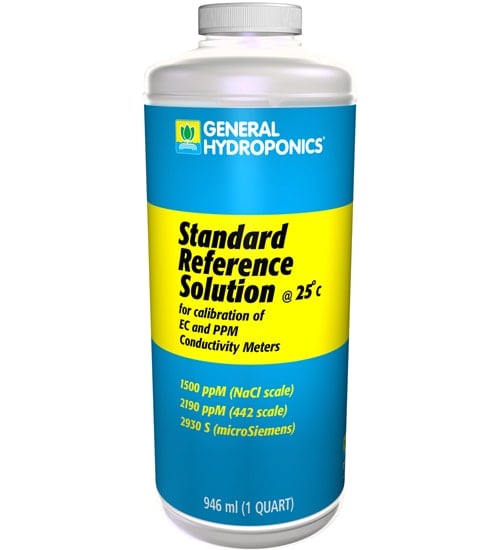

| Figure: A typical TDS/EC meter calibration standard. If you try applying the formulas above, the conversion factors are higher than 0.5 for NaCl and 0.7 for 442. |